Categories

New Blog

Acrylic Assembly Display Stand-Advantages:

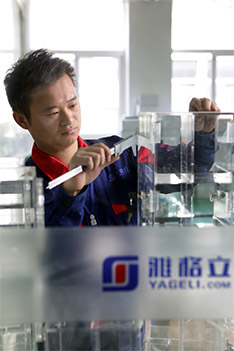

Acrylic assembled display racks are mainly for the transformation of traditional acrylic display racks. With the continuous development of acrylic display racks, the demand for acrylic display racks has gradually increased. Various demand providers are located all over the world. For the problem of acrylic display rack loss when shipped from different places, it has always been a problem that plagues many manufacturers. Acrylic assembly display racks are mainly used to cut a single acrylic board by assembling, leaving a snap position, and it can be spliced and assembled into an acrylic display rack when in use. Acrylic assembled display racks do not use the traditional acrylic display rack gluing processing method, which avoids the conventional problems of glue cracking during the use of acrylic display racks.

Acrylic Assembly Display-Processing Method:

Acrylic assembly display racks are mainly carved by laser machines. Since the acrylic assembly display rack involves cutting a large number of irregular parts, in addition to ensuring a smooth and smooth cutting position, laser engraving is the best choice for acrylic assembly display racks.

Acrylic Assembly Display-Processing steps:

First, design the exploded view of the assembled display rack, and import the design drawings of the acrylic assembled display rack into the laser cutting machine for program decomposition. Then laser engraving processing, processing into acrylic assembly display rack parts, the cut acrylic assembly display rack parts are packaged with plastic film and sent to the buyer, and finally, according to the manufacturer's matching splicing drawings, the assembly and assembly.

Attention:

Acrylic assembled display rack itself is relatively brittle, so do not use too much force when assembling and assembling, which may cause product damage.